Hello All,

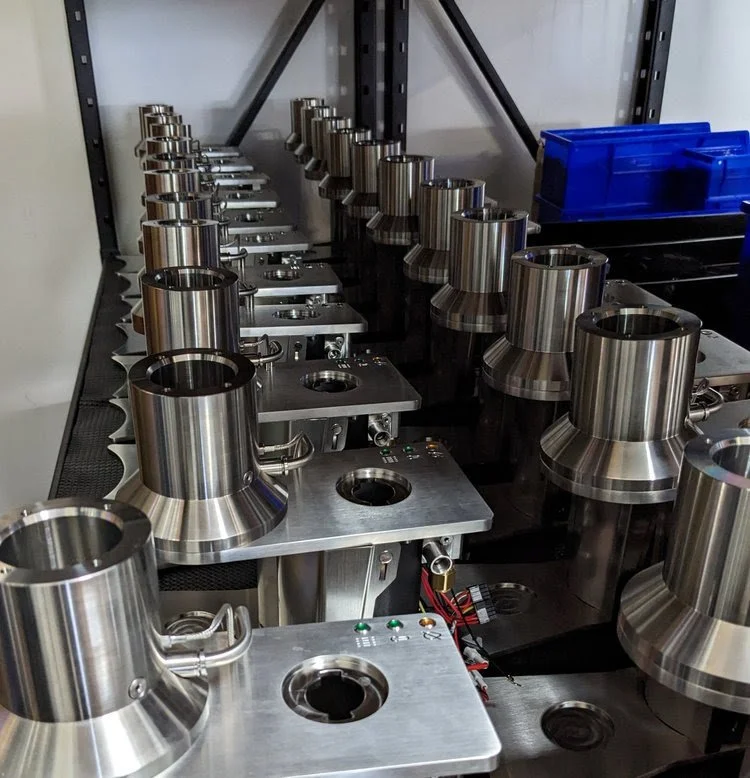

We’re currently up to Order 391 which roughly equates to 235 machines shipped! Throughout the last few months we’ve had a handful of machines that have had some issues come up during the QA. It’s taken us some time to resolve them, but we’ll be focusing on getting those out in the next week so that we’re shipping out units in order again.

The past month has been a bit all over the place. A significant focus was placed on getting a better workflow established for repairs. Most of these were early units with small oversights that we’ve found ways to overcome in our latest assembly practices. We’ve also started working out a better system for tracking simple repair parts that can be sent to customers to address lower level issues on their own. Our repair process has improved and we’ll continue to work on ways to streamline communication and the speed at which repairs are completed and sent back to customers. As a reminder, all these repairs were made free of charge to the customer as they are covered under our warranty.

Staffing:

We’re on the hunt to hire another full time employee so that we will ultimately have 1 full time sub assembly/ QC tech, 1 full time machine builder, 1 full time order fulfillment/packaging technician, and 5 part time miscellaneous shop/machine tasks and builders. This will allow us to get closer to our goal of 30+ per week.

Price Increase:

Due to rising costs of doing business, the Argos has now increased in price from $950 to $1100 USD. We set an aggressive goal to manufacture high quality and relatively affordable home espresso machines. A few specific reasons for the increase include growing the team, higher QA costs, and increased customer service. The new full time hire will help us continue to hit those target assembly and shipping numbers. We strive to have great customer service, so as we ship more machines, we have more inquiries and questions that require time and attention. We stand by our product and fix any major issues in our shop or send out replacement parts which take resources to diagnose and address.

Our aim is to continue improving the quality of fit and finish with each batch we build as reflected in the price and time it takes to receive your order.

App Updates:

We’re glad that people have found the app useful even without a transducer. The app shows the brew set temperature, grouphead temperature, and boiler temperature. The app shows what the target boiler temp is and how close the machine is to it. This target boiler temperature is a function of the brew set temp and the grouphead temperature. The lower the grouphead temperature, the higher the boiler temp will be in order to compensate for the grouphead acting as a heatsink. This is the PID algorithm at work. The Argos prioritizes shot to shot brew temperature stability not pre infusion consistency. Being able to see these numbers helps the user know why boiler pressure is low / high.

We’ll keep working on improving the app and addressing any issues that may arise. There is a lot of opportunity in the app to allow for community interaction and education and we hope to start working towards that in the near future.

Website Updates:

Now that we have Argos’s in the wild, we’ll need to work on updating our website to provide more resources on using the Argos and better educating people on the workflow to make coffee the way they want with the Argos. Additionally we’ll plan to have updated product photos, reviews, and more YouTube videos. We’re currently discussing scope with a local product photographer! Down the line will be a revamp of the website and its layout.

Customer Feedback:

“It's compact and silent, heating up in a little over 5 minutes. I didn't get any of the bells and whistles, and am enjoying the simple pleasure of "I want a coffee" and having it in 10 minutes (not like the 45m it took my HX E61 machine). So far so good!” - (HomeBarista)

“The taste was better than anything I have ever achieved with my sage machines. It was actually quite eye-opening because I had pulled the same beans (natural - brazil - medium/light) yesterday on BBE (though tbf, the grind was too fine for that pull). As someone spending too much time here with money blocked for +2years, I had very high expectations and argos exceeded those.” - EAF Discord

“It has turned out so far that this is a great machine for just doing your stuff without worrying about trying to get the machine to exactly where you want it. The PID and software is great, I think, it just seems to work. I usually turn the machine on and wait a couple minutes, then start prepping. The Craig Lyn shaker is my new fav tool, i just grind straight into it then put the lid on and shake it about for a bit. 1) I usually make 1 espresso for me, then 2) a cappuccino for my wife, pushing the steam button as the coffee pull for her is halfway through (use 8 bar spring). Just a little bit of waiting and poof here we go steaming. Then my middle son comes up and wants an espresso, I just do what Ross did in his process video and turn off the steam, letting some more steam out, wiggle the lever a bit for cleaning and 3) prep and pull the 3rd espresso, no waiting for temp to cool down really . Often I don’t even wait for the green led to turn on again. It is all so fast and the machine does all the temp surfing for me. I am truly flabbergasted!” - EAF Discord

“Dropped down to 88C- pulled like liquid honey! Perfect shots! My friend had a straight espresso. Said ‘passion fruit up front, then buttery mouthfeel, then ended sweet’. Can't get better than that!” - Instagram

Sincerely,

Ross & William