Hello All,

Shipment Updates

Full production shipment of updated bent fill tubes have arrived on May 31, 2023 and fitment is perfect! It takes less than a minute to install the grouphead.

60 back panels with the updated power outlet cutout arrived on May 25, 2023 and also fit as needed

60 back panels are expected to be shipped on a weekly basis

20 packaging sets (molded pulp inserts and outer packaging) shipped on May 31, 2023.

Due to the large size of stacked molded inserts we’re having a difficult time finding an appropriate way to ship these affordably but this is one of our biggest priorities at the moment.

Orders #70-#127 are 75% completed. #70-79 will be fully completed by next week and enter into quality control where we’ll Scace each machine. I anticipate these shipping out by the end of that week. You can now follow along the Order Progress Log here: https://www.odysseyespresso.com/launch-checklist

Certification Updates

Our EMC compliance was completed and passed back in April and the conformance documents are complete which means we can legally sell in the US without issue.

Our final test for the CE certification (required for selling outside of the US) is under way and expected to be completed within 7 days. As long as this test passes, the lab will move directly into conformance reports to declare our compliance.

Once we confirm passing with the lab, we can comfortably start shipping machines with the required mark while the final documentation is being created.

User Testing

We asked a local follower of the Argos if they would take one home and use it daily in exchange for unfiltered feedback so that we can be proactive in creating guides/materials for using the Argos and be aware of any potential issues from a first time user’s perspective. This user is an espresso enthusiast but is not a lever expert. I know we have plenty of people happy to volunteer to help us in this way, but we’re not seeking any more testers at this time.

Here are some of the initial findings

Switching piston assemblies from direct to spring and vice versa is not the easiest task. It took this user just over 1 hour to complete their very first time. While it takes me about 5 to 10 minutes to complete, I do want to make people aware that it will take time for users to feel comfortable performing the swap and is not something I would anticipate doing on a daily basis. I personally prefer switching every month or so.

There are quite a few simple notes I’ll be adding into the User Manual for general safety (like reminders about what is hot to the touch) and usability.

This user prefers the direct configuration. To fully optimize the pressure and yield in the spring configuration can take time to get a feel for at what point in the pull and for how long to let the air bleed out.

It can be a difficult process to dial in beans on this machine. The Argos performs the best in terms of pre-infusion and yield on the first 3 shots. If shot to shot drastically different beans are used, then dialing in may take some time due to waiting for the grouphead to cool

We plan on making more video content discussing these aspects of the Argos as well as better documentation/tutorials on swapping piston assemblies and tips/tricks on making the best coffee with the Argos.

Spare Heating Elements

As a reminder, we used to offer spare heating elements with the main intention being that customers traveling between 120v and 240v countries could swap between the two. After building up the first 50+ machines and having to disassemble and swap gaskets on the boilers to address the leaking, we’ve realized that this isn’t really conducive for the end user to do. It requires near full disassembly and could take over 8 hours by an untrained technician with proper tools. We know many people after reading this might not be interested in a spare heating element anymore, so we’re happy to offer a refund on any existing spare heating element orders. Please contact us through our website or email support@odysseyespresso.com requesting a refund.

The simplest option for people wanting to travel with their machine is to purchase the 240V machine and use that same machine at 120V. The only difference between the machines is the resistance of the heating element. A 240V machine used at 120V will have ¼ the power (250W) instead of 1000W. This will only delay the heat up time. Using a 120V machine on 240V power will have 2000W which may be too excessive for this small of a machine resulting in inconsistent PID control.

Technicians

We’ve got one new assembly technician starting today and another that we will be sending an offer to.

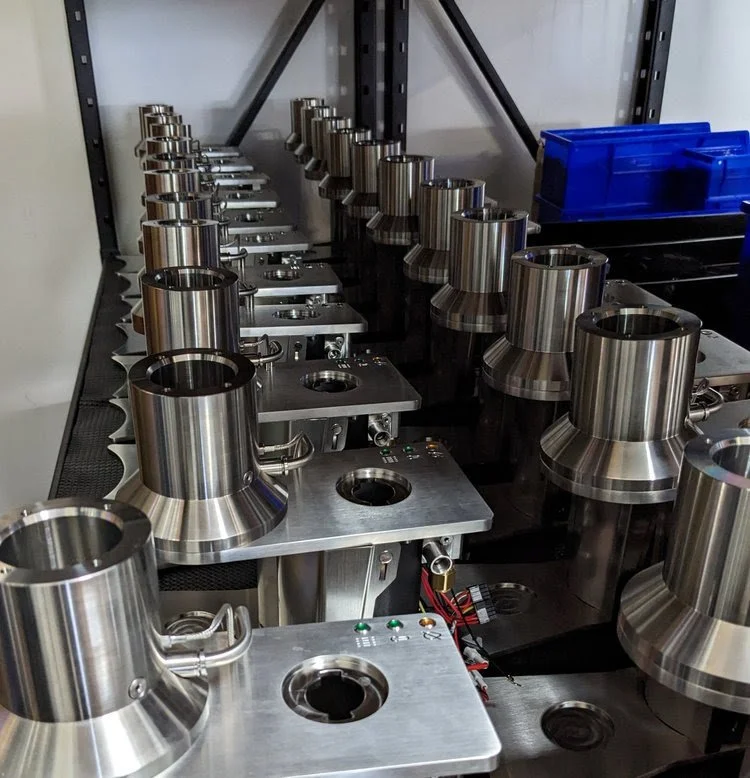

Machines awaiting the final assembly stage.

More machines awaiting the final assembly stage.

Hydrostatic pressure testing the boilers before they move onto stage 2.

Getting wired up.

Sincerely,

Ross & William